A fiber optic faceplate is the optical equivalent of a zero-thickness window providing a high dielectric strength vacuum interface that can also be used for field-flattening, distortion correction, and contrast enhancement. Incom’s fused fiber optic faceplates use total internal reflection to transfer an image from the input surface to an output surface. Faceplates are available in round, square, concave, or convex surfaces. They are used for cathode ray tubes, image intensifiers, CCD/CMOS windows, image plane transfer devices, enhanced displays, and X-ray blocking applications, among others.

Enabling the vision of tomorrow through enhanced digital radiography.

Incom’s medical and dental fiber optic faceplates are a key technological component to the digital radiology industry. These faceplates enable doctors and dentist the ability to view instant, high resolution images while reducing the intensity of X-ray exposure to CCD and CMOS sensors. The fiber optic faceplate acts as a substrate for the scintillator in the detector system, while reducing noise, protecting the sensor, and improving contrast. Incom has the ability to create faceplates to any customizable size up to 49cm X 32cm.

Features

Applications

Normal Abdominal X-Ray

Imaged Through an Incom Fiberoptic Faceplate on a CMOS Based Detector

Incom has created a low-browning glass fiber optic (Radiation Hard Glass) optimized for high radiation dose applications such as NDT. Many standard fiber optics not optimized like this material would brown over time and exhibit reduced transmission from what was originally measured. Incom’s Radiation Hard Glass is manufactured to the same chemistry as our standard FOPs, but is chemically doped to keep the glass from browning—eliminating the concern.

Enabling the vision of tomorrow through lightweight, low cost imaging.

Incom is the only company in the world producing polymer fused fiber optic faceplates for imaging applications. Their technology allow for applications that would never have been possible due to high weight and cost of glass fiber optics. However, as with glass fiber optics, this production ready technology transfers images from the input surface to the output surface with high uniformity, true color fidelity, and minimal distortion.

Features

Applications

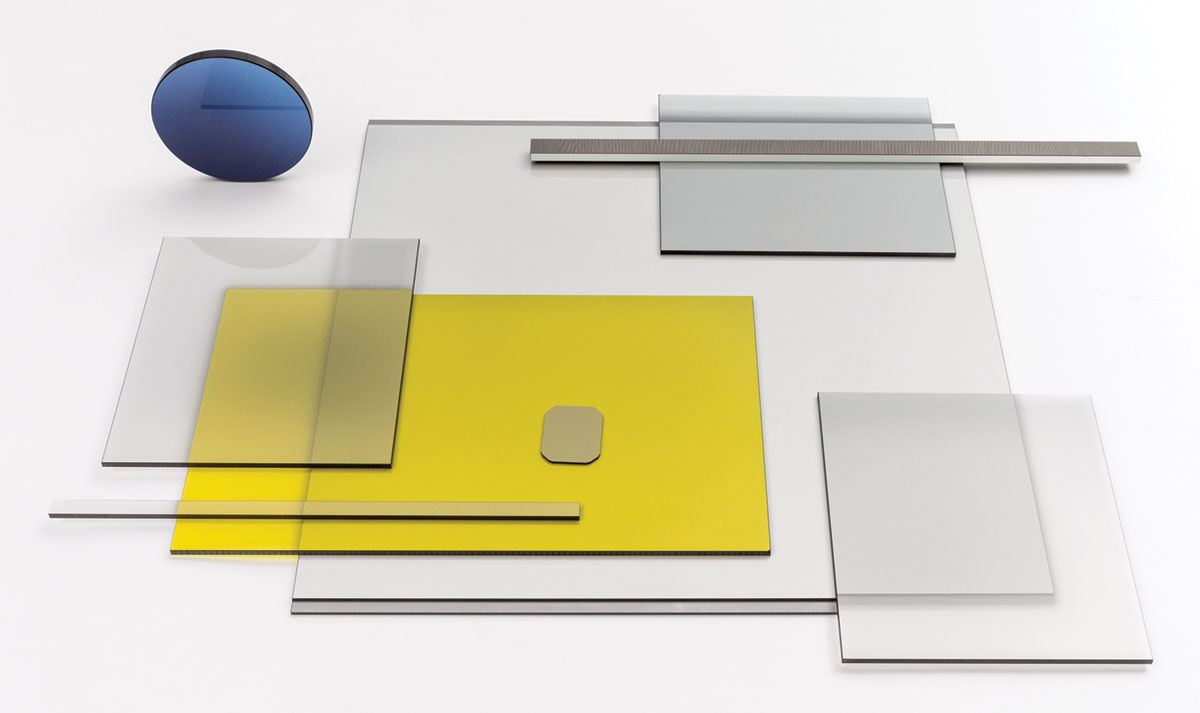

Polymer Fiber Optic Pieces